How to calculate the carbon footprint of cardboard packaging – a practical guide for entrepreneurs

![plan_be_eco_[Jak liczyć ślad węglowy opakowań tekturowych – praktyczny poradnik dla przedsiębiorców]_[pl]](https://planbe.eco/wp-content/uploads/2024/03/plan_be_eco_Jak-liczyc-slad-weglowy-opakowan-tekturowych-–-praktyczny-poradnik-dla-przedsiebiorcow_pl-1024x536.png)

In today’s global environment, there is increasing attention placed on actions leading to sustainable development and environmental protection. One of the key areas garnering growing interest is the reduction of carbon dioxide emissions and minimizing the carbon footprint. In the context of this challenge, more and more businesses are focusing on the ecological aspects of their packaging, acknowledging their significant impact on the overall emission balance.

Cardboard packaging constitutes a significant element in many supply chains, being utilized across a wide spectrum of industries from food to industrial sectors. However, despite their ubiquity, understanding their environmental impact, particularly their carbon footprint, is not always obvious to entrepreneurs.

In this article, we aim to present a practical guide for entrepreneurs who are striving to understand and minimize the carbon footprint of cardboard packaging in their operations. We will discuss not only methods for calculating the carbon footprint but also present strategies for reducing carbon dioxide emissions associated with the production, distribution, and disposal of cardboard packaging. By implementing the practical tips outlined in this article, entrepreneurs will be able to effectively introduce measures aimed at reducing the negative impact of their operations on the environment, while also ensuring the operational efficiency and competitiveness of their businesses.

Highlights

The carbon footprint of cardboard packaging can be calculated using GHG Protocol-based carbon footprint calculators, taking into account the full life cycle of the product, including raw material acquisition, production, transportation, and recycling or disposal.

Reducing the carbon footprint of corrugated packaging is achieved by selecting environmentally certified materials, optimizing the use of packaging, and selecting manufacturing processes that use renewable energy and effective supply chain management.

Innovative practices such as recycling-friendly packaging design, the use of biodegradable materials, and the introduction of reusable packaging help reduce CO2 emissions and increase companies’ environmental credentials, as the examples of Nike and Boxed Water are Better show.

What is a carbon footprint and how to calculate it?

Carbon footprint, or carbon dioxide equivalent per functional unit of a product, is a measure that shows how much greenhouse gases a product, organization, person or service emits. These gases can be emitted directly, such as during production, or indirectly, such as through transportation. But how do you calculate a product’s carbon footprint?

Calculating a carbon footprint is a process that depends on many factors. First, you need to identify all the sources of emissions associated with a product or service, and then focus on those that have the greatest impact. Carbon footprint calculators such as Plan Be Eco can help calculate CO2 emissions, based on energy consumption data and other emission sources such as travel or fuel consumption.

Accurately calculating a company’s carbon footprint, however, requires deeper analysis. Data on:

- energy consumption

- materials and production methods

- transportation

- waste management

All this affects the carbon footprint of a product such as cardboard, among others.

Learn more about the carbon footprint from this article.

Methods for calculating the carbon footprint of cardboard packaging

When we talk about calculating the carbon footprint of cardboard packaging, there are several tools at our disposal. For example, carbon footprint calculators allow you to enter packaging-specific data, such as weight, material type, or transportation distance, which contributes to an accurate emissions result. These methods must be based on international standards and comply with current regulations.

Most importantly, however, it is necessary to take into account emissions from the full life cycle of the product to calculate the carbon footprint of cardboard packaging. This includes:

- raw material acquisition

- production

- transportation

- recycling or disposal process

Each of these stages has its significance and affects the final result of CO2 emissions.

Impact of materials on the carbon footprint of cardboard packaging

The choice of appropriate materials is fundamental in packaging production, as it impacts the carbon footprint. For instance, selecting materials like FSC or PEFC-certified paper ensures they are sustainably sourced, positively affecting the carbon footprint.

Since the 1990s, a distinctive FSC logo has been present on wood and paper products and packaging, indicating responsible forest management certified by FSC. This non-profit organization sets standards for forestry, with its certification system aiming to ensure that material originating from forests comes from responsible sources. This system includes FSC FM certificates for forest managers and FSC CoC for businesses in the timber, paper, and furniture industries.

In Poland, where FSC certification has been active since 1996, we are one of the leaders in this system, with 6.4 million hectares of certified forests. Polish companies, recognizing growing consumer expectations, increasingly opt for certified materials, leading to a steady increase in FSC CoC certificates, reaching 898 as of November 22, 2021. This trend reflects the growing environmental awareness among consumers, who prefer FSC-labeled products, and the tendency of large firms to consider ecological criteria in their procurement policies.

Selecting suppliers committed to environmental care and reducing their own carbon footprint also helps companies adapt to green practices during production, reducing overall greenhouse gas emissions. Additionally, local suppliers contribute to lowering greenhouse gas emissions.

Another important aspect is reducing the amount of packaging used. Removing unnecessary elements and using recycled materials significantly reduces the carbon footprint of packaging.

Corrugated Board vs. Solid Board

When comparing corrugated board and solid board, it’s worth noting that both materials have unique properties affecting their carbon footprint. Corrugated board, due to its structure, is heavier and thicker, which may impact transportation and production costs. On the other hand, solid board is lighter and thinner, potentially contributing to reducing the carbon footprint.

Recycling potential is also a crucial factor for both materials. Corrugated board is easier to recycle and often used to produce new packaging, reducing CO2 emissions. Solid board, due to its properties, may be more challenging to recycle, affecting its carbon footprint.

Ultimately, the choice between corrugated and solid board depends on various factors such as product requirements, production and transportation costs, and recycling capabilities. The final decision should always consider environmental impact, not just raw material cost.

Carbon footprint of corrugated cardboard

![plan_be_eco_[Jak liczyć ślad węglowy opakowań tekturowych – praktyczny poradnik dla przedsiębiorców]_[pl]_tektura_falista](https://planbe.eco/wp-content/uploads/2024/03/plan_be_eco_Jak-liczyc-slad-weglowy-opakowan-tekturowych-–-praktyczny-poradnik-dla-przedsiebiorcow_pl_tektura_falista-1024x536.png)

The European Federation of Corrugated Board Manufacturers (FEFCO) has announced that the new CO2 footprint for corrugated boards in 2022 is 491 kg CO2e/t, a significant improvement over the 2018 result (531 kg CO2e/t). This data comes from the FEFCO and CCB (Cepi ContainerBoard) database and CEPI and CITPA methodologies, confirmed by Ifeu – Institute for Energy and Environmental Research Heidelberg GmbH. Based on renewable raw materials with a high proportion of recycled materials, corrugated packaging is flexible in design, enables efficient storage, and allows for transparent tracking of the CO2 footprint.

Production process optimization vs. carbon footprint

Optimizing production processes is another key aspect in reducing the carbon footprint of paperboard packaging. For example, the use of combined heat and power plants is the most efficient way to produce the required balance of steam and electricity at many paper mills, reducing energy consumption and carbon emissions.

Almost every stage of production uses electricity. Pulp is processed at high temperatures, the use of dryers, cutters is required – before that, the raw material itself, i.e. paper, which is most often recycled, also goes through several processes – just segregation, processing, transportation. An own source of green electricity will significantly reduce the carbon footprint of the paperboard product.

It’s worth mentioning that although the technology of packaging paper production itself is a company secret, it is necessary to report the supply chain as accurately as possible in order to calculate the carbon footprint.

Transportation and logistics as factors influencing the carbon footprint of packaging

Transportation is an important component of the carbon footprint of packaging, encompassing the CO2 emissions created when raw materials are transported to the factory and then finished products to the warehouse or consumers. Therefore, optimizing the supply chain, for example by consolidating shipments, can significantly reduce the carbon footprint of cardboard packaging.

Using local raw materials and shortening the producer-to-consumer journey contributes to reducing the carbon footprint of transportation. In addition, replacing heavy packaging materials with lighter alternatives and carefully sizing packages helps reduce transportation weight and its carbon footprint.

Efficiently packing pallets and eliminating voids in boxes allows for additional layers on the pallet, resulting in lower transportation costs and carbon footprint. By choosing greener modes of transportation, such as trains instead of trucks, and implementing advanced logistics management systems, companies can further reduce greenhouse gas emissions.

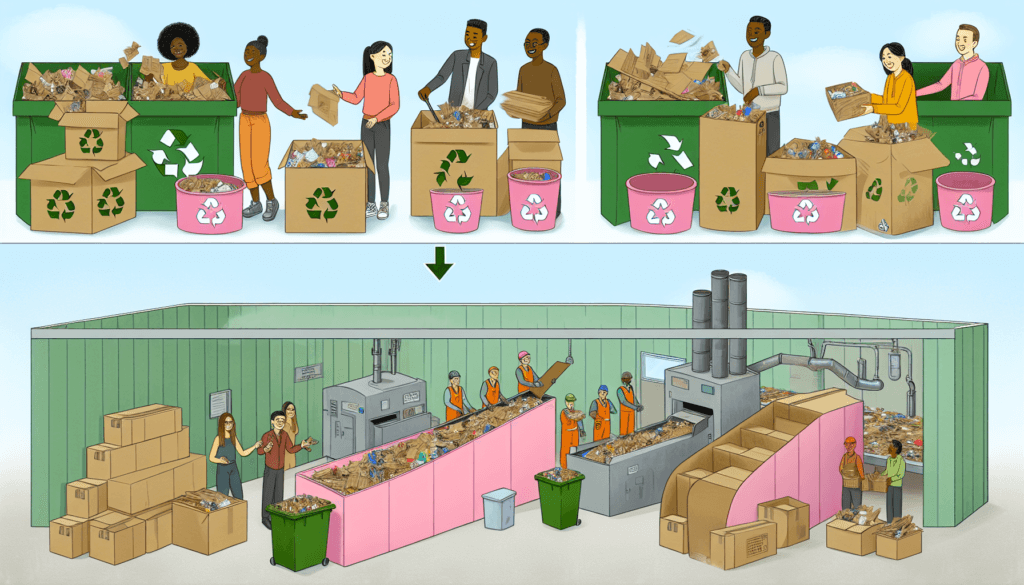

Proper disposal of cardboard packaging, recycling, or composting, is key to reducing the carbon footprint, as it reduces the need for new paper production and methane emissions in landfills. The use of packaging produced from recycled or FSC-certified materials contributes to reducing the end of its life in landfills. Paper pulp is obtained from paper that has been disposed of in a suitable container and recycled.

An interesting example is McDonald’s, which opened its paper production line using used packaging from its products. The company created its circuit, producing towels, toilet paper, and napkins from old food packaging. Read about the process HERE.

Innovative solutions in paperboard packaging to reduce carbon footprint

Transparency and a sustainable approach to packaging production are becoming a priority for manufacturers and consumers, in the context of reducing the carbon footprint. Careful dimensional analysis and the selection of materials with a smaller carbon footprint, such as biodegradable, recycled, or plastic, contribute to reductions in overall CO2 emissions.

Using less packaging and eliminating unnecessary items, as well as introducing reusable packaging reduces the industry’s carbon footprint. Modern materials such as aluminum-free cartons and biodegradable packaging materials are reducing the carbon footprint by reducing CO2 and plastic waste.

Why is carbon footprint reduction crucial for business? READ HERE.

Examples of companies that have reduced the carbon footprint of their cardboard packaging

Reducing the carbon footprint of cardboard packaging can contribute to increasing a company’s popularity in the market, achieving higher profits, and garnering positive consumer opinions about the product.

Nike, a global brand, abandoned double packaging, using shoeboxes as shipping boxes, thereby reducing unnecessary materials and greenhouse gas emissions.

Boxed Water is Better introduced 100% recyclable packaging, with 75% of the paper sourced from responsibly managed forests, while simultaneously supporting forest restoration by reinvesting a portion of its profits.

Some companies, such as Tetra Laval, go even further by using renewable energy sources in their operations. According to their statement, the company has achieved 80% utilization of renewable electricity and is approaching the goal of using 100% renewable energy by 2030.

Other companies, like Oji Holdings in Tokyo, have committed to achieving a net-zero carbon footprint by 2050, employing strategies such as increasing energy efficiency and utilizing renewable energy sources.

In the Polish market, we already see growing interest in reducing emissions from companies producing cardboard packaging. Awareness is increasing due to the need to modernize production lines to be more environmentally friendly. Requirements imposed by the European Union under the CSRD Directive play a significant role, as well as the fact that packaging is part of the supply chain of almost every business.

Summary

The carbon footprint of cardboard packaging is a key aspect that every company should consider. Choosing the right materials, optimizing production, transportation, and disposal processes, and introducing innovative solutions can significantly reduce the carbon footprint. It is not worth forgetting that every decision has an impact on the environment. Therefore, we should strive to make our decisions as responsible as possible.

Frequently asked questions

Is carbon footprint calculation mandatory for SMEs?

No, there is not yet a legal obligation for SME companies to calculate their carbon footprint. However, as of January 1, 2026, small companies will already have to report ESG. But beware – if an SME is in the supply chain of a large, covered company, it must calculate its carbon footprint and provide such information to stakeholders.

How to calculate the carbon footprint?

The best way to check the carbon footprint is to use the international standard described in The Greenhouse Gas Protocol. There are tools on the market that facilitate this process – for example, there is software from Plan Be Eco.

![plan_be_eco_[New guidelines The European Commission recommends reducing emissions by 90% by 2040]_eng](https://planbe.eco/wp-content/uploads/2024/02/plan_be_eco_New-guidelines-The-European-Commission-recommends-reducing-emissions-by-90-by-2040_eng.png)