Carbon footprint and water footprint calculating in the fashion industry

The fashion (textile) industry produces about 10% of annual global carbon dioxide emissions, more than all shipping and international flights combined worldwide. According to the European Environment Agency, the production of clothing, footwear, and home textiles resulted in 654 kg of CO2 equivalent emissions per EU resident, meaning that the textile industry is among the top five sources of carbon emissions linked to private consumption after construction, transportation, and food. Read on to find out how much carbon footprint the fashion industry produces in Poland and Europe. The European Environment Agency indicates that the textile industry uses about 79 billion liters of water annually, not just for fiber production.

Table of content

Textile production vs. water footprint and CO2 emissions

- The fashion industry (including cotton farming) uses about 93 billion cubic meters of water per year

It takes as much as 3,781 liters of water and 33.4 kg of CO2 equivalent to drive 111 kilometers or watch 246 hours of television on the big screen to produce one pair of jeans.

Textile dyeing is the second largest water polluter globally

2,700 liters of water are needed to produce 1 t-shirt, the amount required by an adult for 2.5 years.

The apparel industry generates up to 3 billion tons of CO2 into the atmosphere each year, accounting for about 10 percent of GHG greenhouse gas emissions worldwide. 85 percent of all textiles produced end up in landfills each year

The study shows that a lack of change in the textile sector will result in a doubling of the industry’s greenhouse gas emissions by 2030. At that time, fashion will emit as much as 2.7 billion tons of CO2 equivalent.

Electricity consumption in apparel manufacturing vs. climate change

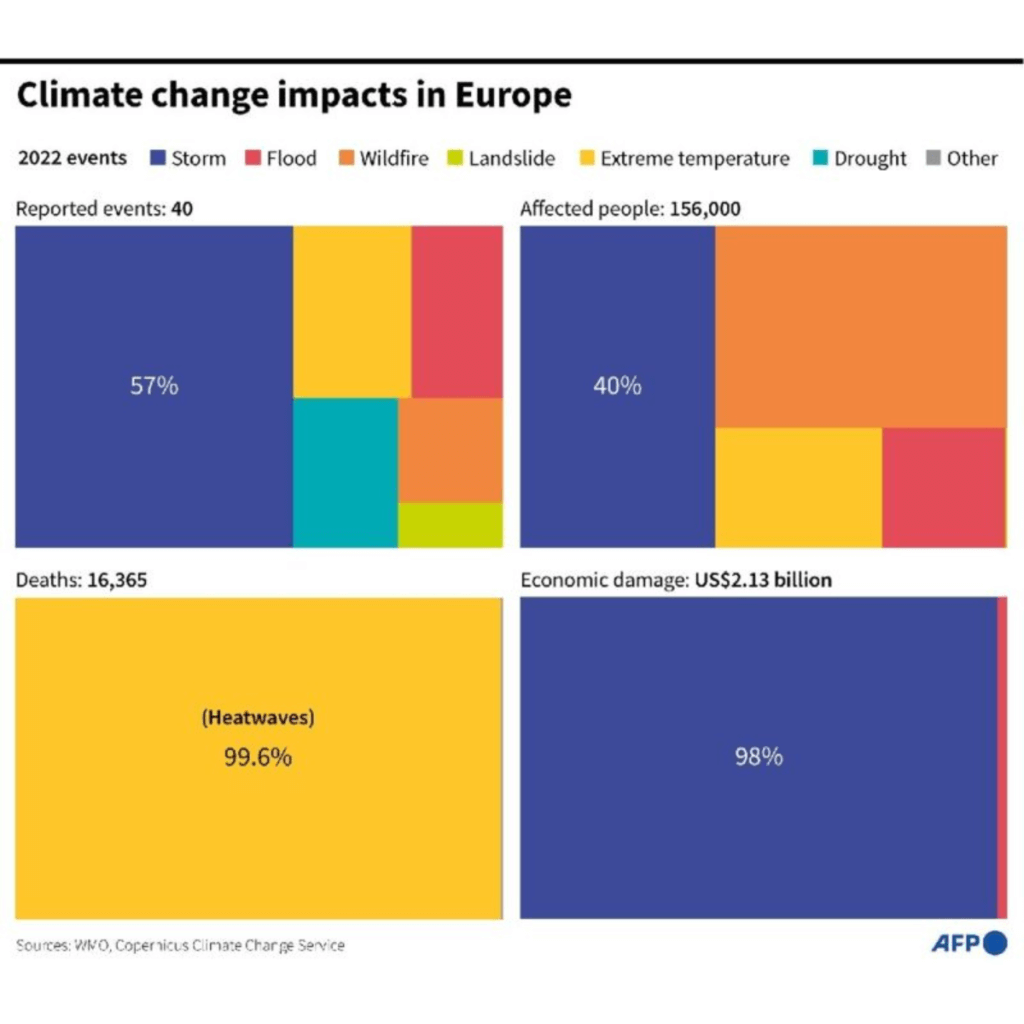

In Europe in 2022 only:

❗ 40 events bearing the hallmarks of extreme weather events, such as hurricanes, floods, and droughts, were reported, and this in turn affected the lives of 156,000 people

❗ 16,365 people died (mainly due to heat waves)

❗ cost Europe more than $2 billion

Scientists are convinced that the main cause of climate change is humans and the carbon emissions they generate. At the current rate of growth in apparel production, the textile sector could use up more than a quarter of the world’s carbon budget by 2050.

Apparel and fast fashion manufacturing has a significant impact on climate change. The apparel industry often uses machinery and equipment with high electricity consumption, which often comes from fossil fuels such as coal, natural gas and oil. Burning these fuels contributes to CO2 emissions into the atmosphere. Textile production requires raw materials, the extraction, production, and transportation of which involve greenhouse gas emissions and environmental degradation.

The garment industry generates large amounts of waste, which may end up in landfills or be incinerated. It has been calculated that every second the equivalent of a garbage truck full of clothing is incinerated or sent to landfills. In addition, some manufacturing processes generate toxic chemical waste. And how about water? For example, growing cotton, especially in arid regions, can require significant amounts of water, which hurts water resources and ecosystems. Textiles are the third largest sector in terms of water consumption and land use.

What goes into a clothing's carbon footprint?

The carbon footprint of textiles measures the emissions of greenhouse gases (carbon dioxide, nitrous oxide, or methane) generated throughout a garment’s life cycle. This includes emissions from raw material production, manufacturing processes, transportation, retail operations, and end-of-life disposal. Key contributors to a garment’s carbon footprint include energy consumption, fossil fuel use, and the production of materials such as fibers, dyes, and finishes.

Production of materials

The production of textile fibers, such as cotton, polyester, and synthetic fibers, often involves energy-intensive processes and the use of fossil fuels. For example, the cultivation of cotton requires significant use of water and pesticides, while the production of synthetic fibers involves the extraction of non-renewable resources.

Manufacturing processes

The production stage contributes to the carbon footprint through activities such as spinning, weaving, dyeing, finishing, and folding garments. These processes require energy and water consumption and often involve the use of chemicals and heat, which contributes to greenhouse gas emissions.

Transportation

The carbon footprint of apparel is also affected by transportation activities, including the movement of raw materials, components, and finished products throughout the supply chain. Long-distance shipping, airfreight, and distribution to retail outlets can result in significant emissions.

Consumer use

Do we generate a carbon footprint by wearing our clothing? Factors such as the electricity used for washing, drying, and ironing, as well as the overall lifespan and disposal, all have an impact on the environment.

Water footprint in the textile industry

The fashion industry’s water footprint refers to the amount of water used throughout the garment production process, from raw material cultivation to manufacturing and laundering. It includes both direct water use (e.g., irrigation in cotton cultivation) and indirect water use (e.g., water consumed in the production of chemicals used in textile processing).

The first generator of the water footprint is fiber production. The cultivation of natural fibers, such as cotton, and the production of synthetic fibers require significant water resources.

Further stages of textile production, such as dyeing, involve significant water consumption. These processes often require repeated washing and rinsing, resulting in the discharge of wastewater contaminated with dyes, chemicals, and pollutants.

The water footprint of garments is also influenced by consumer behavior, including frequency of washing and water conservation during laundering.

Carbon and water footprint using the example of buying one T-shirt

Cotton production process – cultivation, farming, plenty of water for irrigation

transportation of cotton to the weaving site

then the sewing room, the process of cutting, dyeing, sewing – energy- and water-intensive

transportation (usually) from far Asia to Europe (by ships powered by mazut – a highly emissive fuel used in shipping)

packaging – cardboard boxes, plastic wrapping, tape, fillers, etc.

selling – (stationary or online – remember the digital carbon footprint of e-commerce)

using – washing, drying, ironing

disposal – yes, the entire life cycle of the product is considered, the disposal process also matters

Reducing the carbon and water footprint of apparel requires the adoption of sustainability practices and initiatives throughout the fashion industry. This includes promoting the use of environmentally friendly materials, paying attention to energy efficiency in production processes, implementing water-saving technologies, optimizing transportation logistics, and encouraging responsible behavior among consumers.

How to reduce greenhouse gas emissions in the fashion industry?

Textile companies should take steps to reduce GHG emissions at all costs. First – convince investors that calculating the carbon footprint, both of the company and its products with a tool compliant with the GHG protocol corporate accounting is a necessary step, including business. Reducing the carbon footprint is essential for business, and achieving a company’s climate neutrality helps combat the climate crisis.

It is worth implementing ESG projects, betting on a closed-loop economy or renewable energy sources when supplying the company with electricity. It is necessary to revise the working conditions of employees so that they are properly paid and with the support of the employer can create a better quality product.

Reducing GHG emissions, or in other words reducing the carbon footprint, is necessary to meet European Union standards. It’s not worth leaving carbon footprint calculations to the last minute, it’s worth looking at how net-zero, or zero-emission, companies operate, or those that boast that they have gained not only financially by reducing emissions.

Sustainability in the textile industry

Sustainability in the fashion industry refers to the adoption of practices and strategies that minimize the negative social and environmental impacts of garment manufacturing, distribution, and use. It involves, for example, ensuring fair wages, safe working conditions and protecting workers’ rights throughout the supply chain. Moving to a production model based on a circular economy is essential. This includes designing products for durability, recyclability, and ease of repair.

Using environmentally friendly and socially responsible materials is critical. This includes reducing dependence on non-renewable resources, minimizing water and energy consumption, and choosing materials with a lower environmental impact, such as organic cotton, recycled polyester, or innovative alternatives such as plant-based fibers. It is also important to reduce waste, reuse and upcycle materials, and support initiatives such as garment lending, secondary markets, and clothing exchanges.

Promoting transparency throughout the supply chain allows consumers to make informed choices and, in a way, forces a sense of responsibility on brands. Disclosure of information about sourcing, production processes, and social and environmental certifications is essential. It is also important to educate consumers, who will be able, with the knowledge they gain, not only to make informed choices but also to undertake garment repairs.

Politics vs. climate neutrality of the fashion industry

Is carbon footprint calculation mandatory? There are legal instruments to reduce carbon emissions. Policies matter for the climate – such as the Paris Agreement’s commitment to achieve climate neutrality by 2050. ESG reporting regulations already apply to large companies under the CSRD (corporate sustainability reporting directive), which the European Commission adopted late last year, and which will also apply to small and medium-sized companies shortly.

The fashion industry will also need to implement legal solutions that will facilitate the counting of the textile industry’s carbon footprint with the entire value chain, and environmental protection above all. Experts point out that the EU has high restrictions on textiles produced and imported into Europe, if only in terms of chemical concentration levels. It is expected that shortly, this will also apply to the reporting of GHG emissions – already a report created based on the GHG protocol is required to work with large EU investors.

What can we do as consumers?

Our consumer choices and also our lifestyle of using textiles has a huge impact on greenhouse gas emissions. Everyone needs clothing, the vast majority of us, however, have too much of it. We often buy on impulse, not because we need something, but because there is a promotion right now. However, it is very often the case that the price of clothing, which seems attractive to us, is actually much higher than the production price. Why does this happen?

Most textile production takes place in Asia, where European standards of production and fair wages are not common. Unfortunately, when we buy from low-priced chain stores, we are most often supporting companies that do not care about workers’ working conditions. By buying locally, not only do we have the influence and ability to control the working conditions of those who make our clothes, but we also reduce the need for high-carbon shipping. Consciously buying better quality clothing will ensure that a product can stay in our closet longer.

First of all, it is worth verifying the need to purchase. Remember that the most sustainable clothes are the ones we have in our closet. However, if purchases are necessary, it is worth choosing the second circuit. In addition to saving a lot of money, used clothing is a real environmental impact measure.

Take a peek at the eco-impact calculator we created with Ubrania do Oddania (Clothes to Donate) and see how much you can save by opting for second circulation.

What is the Cost Per Wear factor?

Cost Per Wear, or the cost of wearing a garment, is the ratio of the price of a garment to how many times it has been worn. This is in response to the charge by fast fashion advocates that sustainable clothing is too expensive. In practice, when one buys a good quality garment and it lasts for years, its CPW will be lower than that of a cheap garment that will be unusable after one season.

In this simple way, consumers can verify the real price of clothes, and consciously plan their closet selection and budget. The lowest CPW is, of course, second-hand clothing.

Consumers’ environmental awareness is growing, and it’s becoming more common for them to opt for the option of recycling their clothes – repurposing, proper maintenance or refurbishing will allow them to enjoy their clothes longer. Consumer choices such as conscious buying, using energy-efficient washing machines, and washing clothes at lower temperatures can help reduce the water footprint.

It’s worth forcing transparency on manufacturers. Ask about their manufacturing process, certifications, the organization’s carbon footprint, or how they take care of the entire life cycle of products. Do they perhaps have renewable sources of electricity in use? Consumers cannot be held responsible for the overproduction and unreliability of textile product creation.